Cylinder Heads

(03) 9305 4840 · 9 Leader Street, Campbellfield VIC 3061 · Mon-Fri: 8am-5pm

Reflex Automotive Engineering has been specializing in new, exchange & reconditioned cylinder heads since 1988, from your single cylinder motorcycle engine or twin cylinder jetski to your family car or heavy diesel engine.

We have over 600 changeover and new cylinder heads in stock ready for fitting, and to make the job easier we have a large range of VRS gasket and head bolt sets to suit all our cylinder heads.

The most important thing about reconditioning your cylinder head is that you know that it will be done right the first time. Reflex Automotive Engineering is a licensed VACC Engine Reconditioner, with highly qualified and licensed tradesman and apprentices. We are quality endorsed and have quality endorsed procedures in place; in fact we are one of a few throughout Australia who actually are giving you the confidence and ensuring the job is done right.

Contact us today!Cylinder Head Reconditioning Process

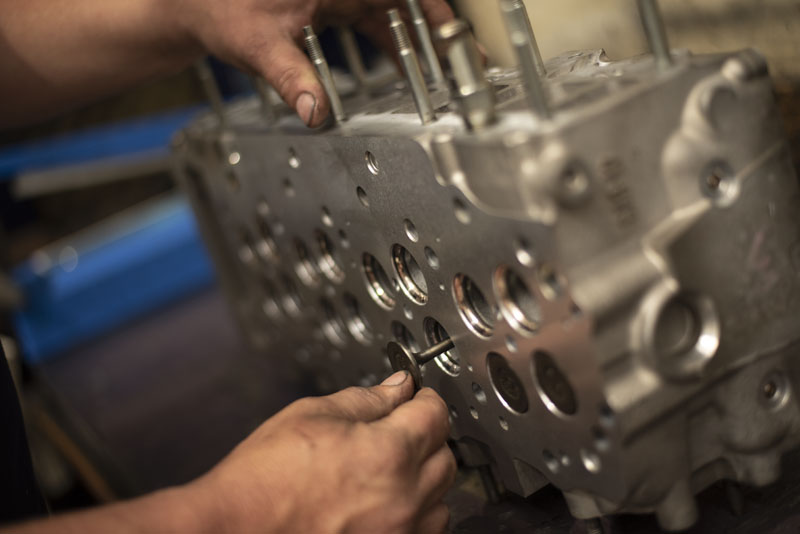

On arrival we allocate a job number and the cylinder head is dismantled, chemically cleaned and inspected, checking valves and valve guides, retainer and collets condition and test valve spring pressures.

The cylinder head core is checked for height, straightness and hardness and pressure tested in a submersible pressure tester checking for any cracks or porous leaks and all threads are checked.

After inspection we prepare a report and quotation as part of the engine reconditioning process and advise you of the cost to recondition your engine which usually can save you hundreds of dollars compared to outright replacement.

Cylinder Head Reconditioning Services

- Dismantle cylinder head

- Chemical clean

- Check valve condition

- Check valve guide condition

- Test valve spring pressure

- Check retainer and collet condition

- Check cylinder head height, straightness and hardness

- Submersible pressure test

- Weld cracks and porous holes as required

- Crack test cast iron cylinder head

- Crack repair as required

- Fit and ream valve guides

- K-line installation

- Install valve inserts for LPG/unleaded

- Machine valves

- Corrosion welding

- Aluminium welding

- Cast iron welding

- Cylinder head straightening if required

- Remove broken bolts and studs as required

- Spark eroding

- Insert or repair stripped threads as required

- Insert spark plugs as required

- Injector tube installation

- Precomp chamber installation

- Valve seat machining (3-angle)

- Surface cylinder head (mill/grind)

- Reface rockers

- Line bore cam tunnel

- Reset valve lengths

- Reassemble cylinder head

- Adjust shim clearances for OHC engines

- Bead blast auxiliary engine components