(03) 9305 4840 · 9 Leader Street, Campbellfield VIC 3061 · Mon-Fri: 8am-5pm

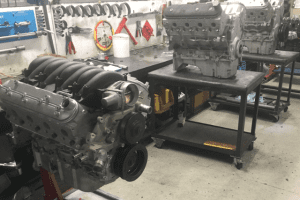

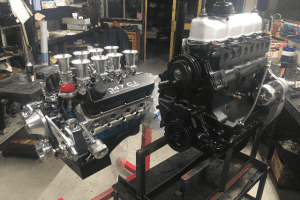

For over 30 years Reflex Automotive Engineering has been providing the automotive, marine, earthmoving and motorcycle industries with unsurpassed machining and engine reconditioning services.

We have forged a reputation in the engine reconditioning industry as one of the market leaders.

With Australia’s most experienced operators utilizing the latest in engine machining technology we offer a cost-effective service. This, coupled with quick job turnaround times and components machined to OEM tolerances in a quality endorsed environment guarantees your engine will be produced at the highest possible standard.

Whether your needs are for resurfacing a cylinder head, or reconditioning a long engine for petrol, diesel, LPG or performance application, Reflex have the facilities, experience and capacity to professionally satisfy your needs.

Contact us today!Engine Reconditioning Process

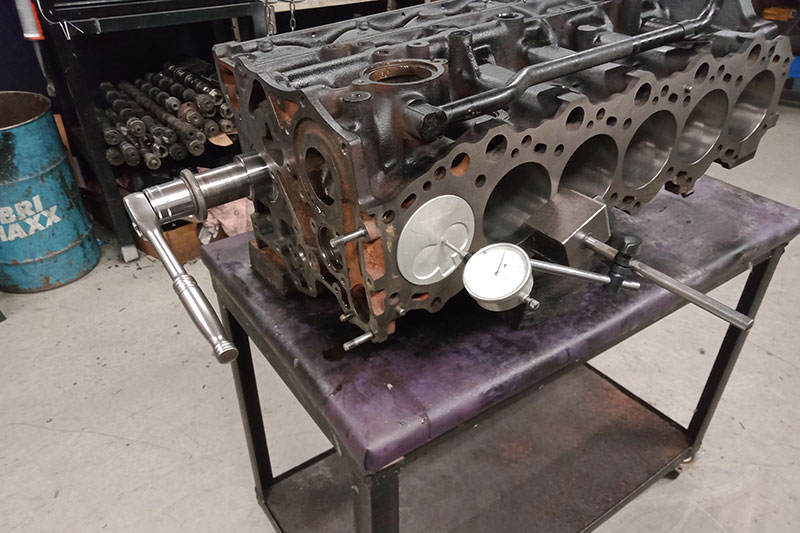

On arrival we allocate a job number. All engines are completely dismantled, all components are tagged with the job number and then are put into the hot tank to be chemically cleaned. When they are cleaned, they are crack tested and measured to OEM tolerance. After inspection we prepare a full report and quotation to advise you of the cost to recondition your engine. Following approval of the quotation, all the components are taken to respective work stations where they are reconditioned.

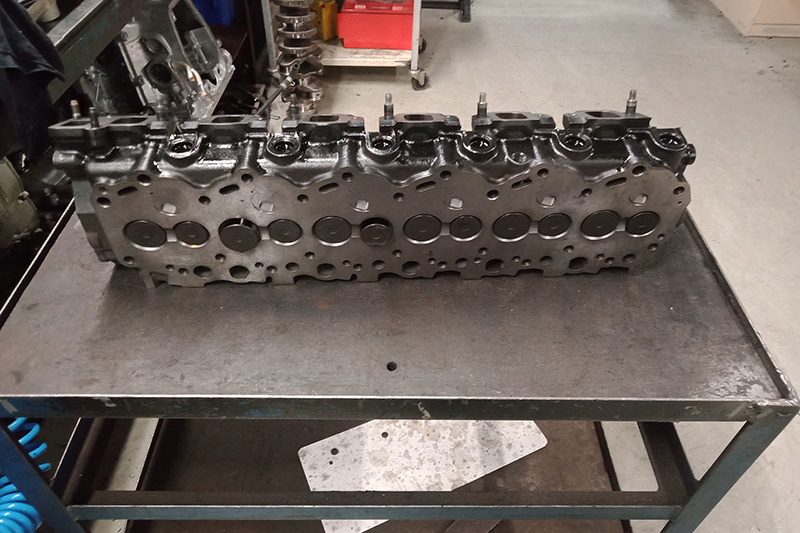

Contact us today!Cylinder Head Inspection & Repair Process

After dismantling, we chemically clean and inspect checking valves and valve guides, retainers and collets condition and test valve spring pressures.

The cylinder head core is checked for height, straightness, hardness and pressure tested in a submersible pressure tester checking for any cracks or porous leaks and all threads are checked.

Cylinder head failure can cause several problems such as poor performance, rough running and engine overheating.

Contact us today!Cylinder Head Reconditioning

-

Crack testing

-

Pressure testing

-

Crack repair

-

Weld porous hole

-

Weld corrosion

-

Weld crack

-

Aluminum welding

-

Cast iron welding

-

Spray welding

-

Straightening

-

Fit valve guide

-

K-line installation

-

Ream valve guide

-

Hone valve guide

-

Fit valve seat

- Fit hardened exhaust valve insert

-

Machine valve

-

Machine valve seat 3 angle

-

Porting

-

Precomp chamber installation

-

Remachine surface

-

Injector tube fitting

-

Machine valve guide for positive fit valve stem seal

-

Oring surface

-

Machine fire ring

-

Line bore cam tunnel

-

Machine spring seat

- Remove refit rocker stud

-

Broken bolt removal

- Machine shim adjust valve clearance

-

Retap threads

-

Fit thread inserts

-

Spark plug thread insert

-

Test valve spring pressure

-

Fit valve stem seals

-

Fit brass/stainless welch plugs

-

Reassemble cylinder head

Crankshaft Inspection & Repair Process

Crankshaft failure will start as a slight noise gradually becoming louder which, If not rectified can cause major damage to the engine.

The procedure for crankshafts starts with crack testing, measuring against OEM specifcations and checking for straightness.

After the testing procedure, the crank is ground to the first possible undersize.

Contact us today!Crankshaft Reconditioning

-

Crack testing

-

Measured to OEM tolerances

-

Weld and machine thrust area

-

Weld nose

-

Machine keyway

-

Linish crankshaft journals

-

Grind crankshaft journals

-

Nitride crankshaft

Conrod Inspection & Repair Process

Our process for reconditioning of conrods involves crack testing, checking small end and big end size and straightness.

After the testing procedure, the conrod is resized, small end bushes are replaced and pin bored.

Contact us today!Conrod Reconditioning

-

Crack testing

-

Alignment

-

Measured to OEM tolerances

-

Remove refit small end bush

-

Pinbore small end bush

-

Resize big end

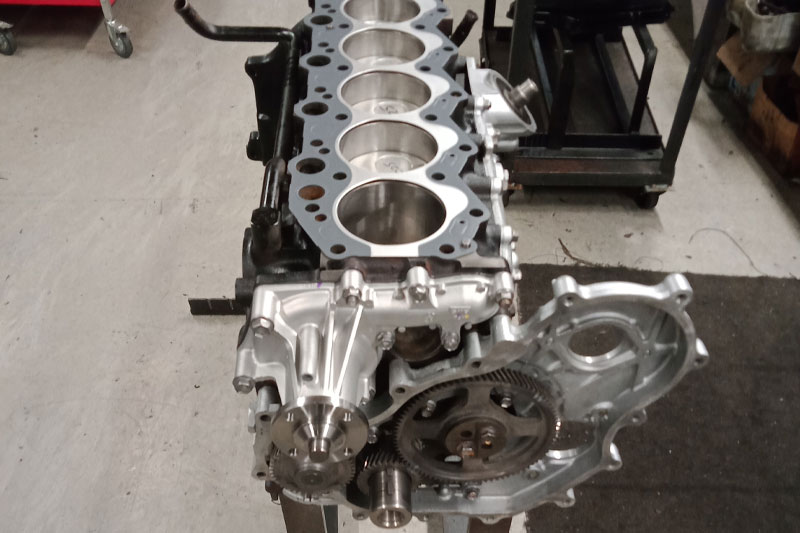

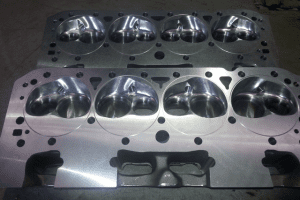

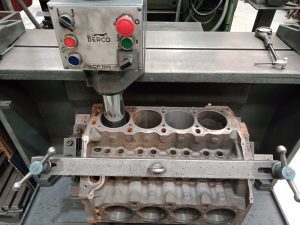

Engine Block Inspection & Repair Process

The block inspection consists of checking cylinder condition, top deck, main tunnel and camshaft tunnel. Depending on the engine condition it will be rebored to the first oversize and top deck resurfaced.

Contact us today!Engine Block Reconditioning

- Crack testing

- Measured to OEM tolerances

- Line bore main tunnel

- Line bore camshaft tunnel

- Salvage sleeve fitting

- Bore and hone block/cylinder

- Cam bearing fitting

- Auxiliary bearing fitting

- Surface block/top deck

- Machine counter bore

- Counter bore insert

- Oring block

- Retap thread

- Thread inserts

- Cast iron welding

- Aluminum welding

- Spray welding

Timing Components

Timing components are checked for wear to determine if replacement with a new timing kit is necessary.

Contact us today!Oil Pumps

Oil pumps are check for wear to determine whether we can rebuild with new components or if the pump should be replaced with a new oil pump.

Contact us today!Camshafts

Camshafts are measured, then linished or reground if the camshaft is deemed too badly worn, and replaced with a new billet.

Contact us today!Full Engine Balancing

If you’re looking for a performance increase, or just to improve your fuel economoy, talk to one of our friendly staff today about engine balancing!

Contact us today!New Engine Components required to recondition an engine

- Oversize Piston and rings

- Oversize main and conrod bearings

- Camshaft bearings

- Thrust bearings if applicable

- Balance shaft if applicable

- Auxiliary bearings if applicable

- Full engine Gaskets set

- Head bolt set if applicable

- Brass or stainless steel welch plugs

- Engine assembly

Specialised Machining and Procedures

- Flywheel Machining Flat/Stepped Passenger Car/Heavy Diesel

- Surface Machine Truck Flywheel Housing

- Surface Machine Truck Gear Housing

- Intake Manifold Valley Cover Surfacing

- Surface Exhaust Manifold

- Onsite Broken Bolt Removal and thread inserts

- Engine Balancing

- Onsite Sparkplug Thread Inserts

- LS Engine Block Thread Inserts

- LS Reluctor Wheel Fitting

- Aluminium Welding

- Cast Iron Welding

- DPF Cleaning

- Torque Plate Honing For Barra Engines

- Torque Plate Honing For LS Engines